AIRBUS A380 : Corner Fittings automated by V-STARS measurement system

“Get it right the first time”, that is the primary concern of engineers and technicians at Airbus in

One critically important step in the assembly of this “flying giant” is the junction of the wings to the fuselage. This sensitive operation requires much planning and expertise. Perhaps the most significant step in the process is the fabrication of the set of “Corner fittings”. These fittings are complex parts – intended to conform to several freeform surfaces – that must be manufactured as close to the existing conditions as possible in order to maximize the integrity of the wing-to-fuselage interface.

In this case, the corner parts must fit precisely to the aircraft without affecting the wing to fuselage relationship. In other words, each aircraft has its own unique corner fittings that must be manufactured in a short period of time. There are eleven parts on each side of the plane (twenty two parts per aircraft). Since so many parts need to be made quickly, a very precise and fast reverse engineering technique of each female corner (concave corner) has to be performed in order to be able to machine the relating corner fittings within the required period of time.

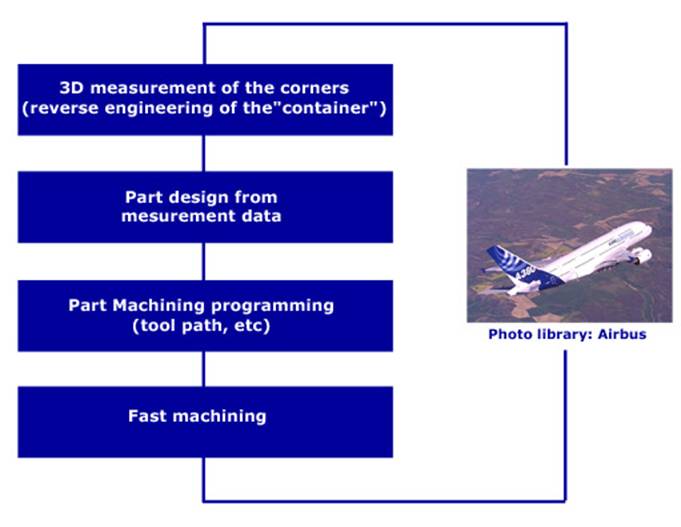

Twenty two “containers”, or cells, must be measured in order to facilitate automated machining and assembly of the corresponding “contents” of the cell. The whole set up - the 3D measurement, corner piece design, five-axes tool-path programming and the fitting of the parts must take place in less than thirty three hours.

Given this imposing requirement, Airbus has chosen the photogrammetry 3D measurement system called V-STARS to perform the reverse engineering measurements of several of these cells. This was an easy choice for Airbus because V-STARS demonstrated the required accuracy, speed of data collection, ease of use and portability of the measurement instrument (the INCA3 camera with WIFI) to be used by the manufacturing operators inside the wing itself. These features of this measurement system provided the means to overcome the obstacles of having to work in a very confined environment, in which vibration and temperature variation as a result of ongoing manufacturing activities were taking place. The INCA3 camera must be able to perform in an environment with an ongoing machine drilling and lubrification. It should also be noted it is not possible to stop other assembly activities so that these measurements can take place. Since cleaning liquids are present, the measurement system could not introduce any danger of igniting these elements.

Below is a diagram showing the main steps of this corner fitting assembly process :

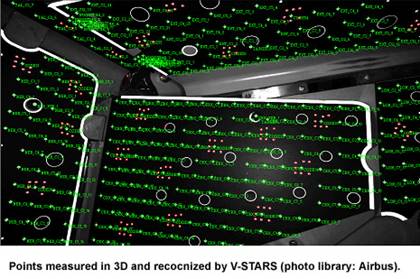

This turnkey system includes the latest generation V-STARS measurement system using the INCA3 digital photogrammetry camera from Geodetic Systems, Inc (GSI). GSI's distribution partner in France and Belgium, Géodésie Maintenance Services, www.geodesie-maintenance.com (GMS), designed adapted retro-reflective targets which significantly makes the set up much easier (see attached picture : operator measuring inside the Airbus A380 wing). Photographic library, copyright : Airbus.

These targets can be applied to the surfaced to be measured very quickly. This makes data collection and processing possible within just a few minutes. Automated post processing of the point cloud data produces information required to make borings and the machining of mating surfaces for the interface between the wing and fuselage.

One step of the measurement process involves the taking of twenty-five to thirty-five pictures. Because the work space is so confined, the operator cannot always position his eye behind the viewfinder of the camera. INCA3 solves this camera aiming problem by providing two aiming lasers. The operator needs only to push a button to see where the camera is aimed. As the images are acquired, they are transmitted via wireless Ethernet to a notebook computer outside of the work area.

Engineers and technicians from Airbus in

The success of this cooperative effort between the V-STARS team and AIRBUS has made it possible to implement the same system with the Airbus A340 and A320 as well.

The INCA3 camera

The INCA3 camera, specifically designed and built by GSI to perform high accuracy 3D measurements, combines a proven ultra-high-resolution CCD sensor with an on-board PC based industrial computer to perform measurements in harsh conditions and unstable environments. In order to obtain such performances, GSI imposes not only an unsurpassed opto-mechanical stability inside the camera but also features such as an integrated strobe, or wireless (WIFI) connectivity after a typical ten-to-one image compression.

The confined aspect of the measurement environment of the corners fitting at Airbus is interesting for the

V-STARS system. However, the INCA3 camera is particularly well-suited for in-place measurements of large objects since there is no size restriction of the part to be measured. That makes it possible for V-STARS systems to be used in fields such as Aeronautics, Space, automotive, shipbuilding, power generation, heavy industry, etc

Once INCA3 captures photos (either via hand-held operation or remote control), GSI's proprietary V-STARS software automatically inspects the collected digital images and extracts the required 3D data. This process is fully automated. The measured points can then be compared to their nominals (either point by point or compared to the relating CAD file) or compared to previous measurements (repeatability or capability studies).

INCA3:

What is Metrology? What is Photogrammetry?

The science of measurement is known as the field of metrology. Engineers, manufacturers, scientists, and quality control technicians utilize measurement technology in their own unique disciplines.

About NTI

NTI manages all aspects of GSI's V-STARS activities in Europe.

About Geodetic Systems, Inc.

Geodetic Systems, Inc. (GSI, www.geodetic.com) is an international supplier of industrial photogrammetry solutions for the industrial measurement/metrology marketplace. GSI develops and markets the V-STARS family of 3D coordinate measurement systems for users involved in measurement and inspection applications in diverse industries such as aerospace, nuclear power, automotive and shipbuilding. INCA3, the company's flagship product, is a state-of-the-art digital photogrammetry camera with many progressive features. GSI distributes its products via a worldwide network of industry partners. The V-STARS systems and the INCA3 camera's distribution in Europe is coordinated by NTI.

For further information contact:

32 route de Seichebriéres

Tel. +33 (0) 2 38 59 30 51 / Fax: + 33 (0) 2 38 59 30 97

Cellular: +33 (0) 6 83 70 89 79

E-mail: nicolas.tanala@v-stars3d.com, website: www.nti-measure.com

__________________________________________________________________________________

INCA3, V-STARS, Picture Perfect Measurements are trademarks or registered trademarks of Geodetic Services, Inc. All other brand and product names are trademarks or registered trademarks of their respective owners.