Innovative metrology for premium trucks.

MAN Trucks demand premium quality from their products. To fulfill this ambitious goal, they are using the most modern metrology in body assembly – the mobile 3D camera system V-STARS from Geodetic Systems, Inc. (GSI). It is, not least, the innovative users of this measuring technology at MAN that have made photogrammetry an irreplaceable tool in solving various tasks.

“There are only a few among our users who use V-STARS in such an extremely flexible manner. At MAN, this is the result of many years of experience and intensive involvement with optical metrology. Here they not only take advantage of using the cameras for testing complex objects in the measuring cell or in production, but also perform measurements on large components directly in the assembly line.

The system is also regularly used for tactile measurements using the manually-guided wireless probe in online mode vs. CAD data. MAN uses the online/offline combination very effectively – absolute top users we would be happy to name as references.... There is always something to learn, even for us“, is how Roland Kinzel, director of GDV Systems GmbH in Bad Schwartau and sales partner of GSI, praises his customers in Munich.

The primary objective of the metrology department, which is located directly in the Body-in-White area at MAN Trucks in Munich , is the dimensional accuracy of the manufactured shells. Activities range from calibration of manufacturing facilities to the geometric monitoring of completed chassis. If tolerance deviations are noted, it is the responsibility of the 8-man team of Jean-Claude Saeul to correct them. For this purpose, the measurement experts have had at their disposal not only stationary coordinate measuring machines and an in-line measurement cell, but – since 1998 – the mobile V-STARS system from GSI as well.

V-STARS is an optical coordinate measuring system whose single INCA camera (V-STARS/S) or two or more INCA cameras (V-STARS/M) make possible quick and highly-accurate 3D capturing. Thanks to the photogrammetric technology, the actual measuring activity does not take place directly on the object, but on digital images that are taken from different perspectives. The photos are then automatically processed by the powerful V-STARS software, and the 3D coordinates of the measured object are calculated – offline or online. The results can be displayed and analyzed directly, graphically or numerically, with V-STARS or another software. The measuring accuracy of the V-STARS/S system is given as 5 µm + 5 µm/m, that of the V-STARS/M system lies at 'only' 10 µm + 10 µm/m due to the lower number of pictures and the tactile probing mode.

MAN Nutzfahrzeuge acquired the mobile system primarily for measuring devices. Until the end of the 90s, this task was still tackled using vernier height gauges and 'cubing,' which was rather complicated and time-consuming. “At that time we established a requirement profile for a new measurement system and joined a benchmark test at Volkswagen. And V-STARS was the only system that matched our vision: It is not sensitive to light, suited for measurements in an unstable environment, and wireless. Eight years ago we acquired a system with INCA1 cameras, followed at the end of 2004 by another one with the current INCA3 sensors, “reports Jean-Claude Saeul.

The first use of the V-STARS system involved the Body-in-White process for a new type of vehicle in Munich in 1998. The tooling for this project was built at a supplier's facility in Osnabrück. That's why the measurement technicians packed the mobile system into their car and drove to the supplier, where all devices were calibrated over a period of several weeks. Then the equipment was dismantled at the manufacturer's premises and reassembled in Munich . The first thing the metrology team did here was check whether the geometry was still accurate. It was a positive comparison measurement. All data that were recorded then are still in the system, by the way, and the metrological specialists are still using these values today.

Fig 1: In the V-STARS measuring cell, where the tactile portion of the component measuring processes is performed, the INCA3 cameras are suspended in mid-air. |

|

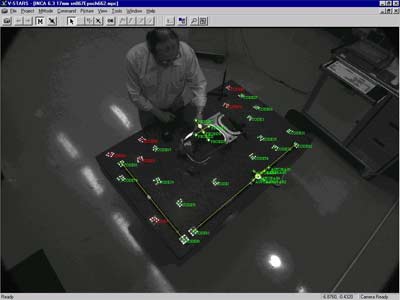

Fig 2: Photogrammetric measuring of deformation in cabs directly during manufacturing. |

Contrary to the original plans, the use of the V-STARS system no longer focuses exclusively on the measurement of devices. “Today we are intensively supporting process analyses directly in production and also measure different components in the measuring cell. The more people see V-STARS in action, the more work comes our way. We are always asked whether critical measuring tasks in other areas can also be solved with the mobile system. The result is that we regularly carry out projects for other departments in Munich and other plants as a service, “says measuring technician Johann Dumele.

For example, an internal measuring service was conducted directly on an assembly line running on a 7-minute cycle. As part of a 100% test, the measuring technicians from the Body-in-White phase captured the actual geometric status in the assembly of fender tubes for two days. For this study, Jean-Claude Saeul's team had developed a comprehensive measuring strategy in advance that would ultimately enable them to compare the actual geometric data with the CAD target values, and to provide extensive statistical evaluations.

During this process analysis, the production status was captured in the offline mode, and the measuring results were then compared using a multi-step process. An additional standard application of this system is component measuring, which is performed during the Body-in-White stage in the V-STARS measuring cell. In the current case, this involves tooling for two components: the end wall and the front wall assembly units. During the same measurement recording process that is also used for the coordinate measuring device, the tooling is calibrated using the offline mode, and it is then checked by touching the hand probe to it using the online mode; i.e., exactly the same way as with a coordinate measuring machine, but considerably faster. This time savings advantage applies to fault analyses in general, since objects are only measured once.

The current highlight, which is also a testimony to the MAN measuring technicians' creativity in applying the system, is the redesigned V-STARS measuring cell: Since it is not very large, but usually filled with components, several tripods would have had to be set up to allow working comfortably in the online mode. However, tripods tend to have the disadvantage of being in the way when they are not in use. That is why our photogrammetry experts suspended their INCA3 cameras ‘up in the air'. Their practical experiences with this bold solution have been great; it has been totally validated. And yet, the folks in Munich are still working on refining their ‘floating measuring device'. For example, they are planning to develop an innovative connection to an electrical outlet instead of relying on rechargeable batteries...

The Body-in-White measuring technicians have an important source of information, additional tricks and ideas for using the optical measuring system in the form of the V-STARS workshops developed by GDV Systems. It is the exchange with users from other industries, such as aerospace, in this venue that keeps pointing out highly interesting solutions to the MAN measuring experts again and again. They rate their cooperation with GDV Systems very highly outside of these workshops, too. The measuring technicians are not only complimentary of the good service, which, however, is not put to use very often due to the high reliability of the V-STARS system, but also of the excellent training that they receive on actual measuring tasks.

This is why it is not surprising that the V-STARS system fully met MAN's expectations. Especially the portability and the ability to work in unstable environments impress its users time and again. Not only because the measurement technicians with the camera system are always ready to go such as when there is a problem on the assembly line in the plant, but also, and especially, because they can travel with the system. The technicians from Munich , for instance, have calibrated and adjusted the production facilities in Gustavsburg and in Steyr on several occasions. In Steyr, the equipment is directly adjacent to the pressing plant, where they know what instability during production means. You can literally feel the weight of the large installations. For this reason, precise calibrations using competitors' measurement systems that require a stable location can only be performed on Saturdays and Sundays when the pressing plant is not in operation.

“Without the V-STARS system we could not be so flexible. Quality assurance in the entire process chain – from body assembly to maintenance to the finished vehicle – has meanwhile been completely reconciled with the photogrammetric measurements. Personnel capacity permitting, we work with the system daily. But we could also easily fill three shifts with applications..., “summarizes Jean-Claude Saeul.

Fig 3: The images are automatically processed by |

|

|

The INCA3 camera

The INCA3 camera, specifically designed and built by GSI to perform high accuracy 3D measurements, combines a proven ultra-high-resolution CCD sensor with an on-board PC based industrial computer to perform measurements in harsh conditions and unstable environments. In order to obtain such performances, GSI imposes not only an unsurpassed opto-mechanical stability inside the camera but also features such as an integrated strobe, or wireless (WIFI) connectivity after a typical ten-to-one image compression.

The confined aspect of the measurement environment of the corners fitting at Airbus is interesting for the

V-STARS system. However, the INCA3 camera is particularly well-suited for in-place measurements of large objects since there is no size restriction of the part to be measured. That makes it possible for V-STARS systems to be used in fields such as Aeronautics, Space, automotive, shipbuilding, power generation, heavy industry, etc

Once INCA3 captures photos (either via hand-held operation or remote control), GSI's proprietary V-STARS software automatically inspects the collected digital images and extracts the required 3D data. This process is fully automated. The measured points can then be compared to their nominals (either point by point or compared to the relating CAD file) or compared to previous measurements (repeatability or capability studies).

INCA3:

What is Metrology? What is Photogrammetry?

The science of measurement is known as the field of metrology. Engineers, manufacturers, scientists, and quality control technicians utilize measurement technology in their own unique disciplines.

About NTI

NTI manages all aspects of GSI's V-STARS activities in Europe.

About Geodetic Systems, Inc.

Geodetic Systems, Inc. (GSI, www.geodetic.com) is an international supplier of industrial photogrammetry solutions for the industrial measurement/metrology marketplace. GSI develops and markets the V-STARS family of 3D coordinate measurement systems for users involved in measurement and inspection applications in diverse industries such as aerospace, nuclear power, automotive and shipbuilding. INCA3, the company's flagship product, is a state-of-the-art digital photogrammetry camera with many progressive features. GSI distributes its products via a worldwide network of industry partners. The V-STARS systems and the INCA3 camera's distribution in Europe is coordinated by NTI.

For further information contact:

32 route de Seichebriéres

Tel. +33 (0) 2 38 59 30 51 / Fax: + 33 (0) 2 38 59 30 97

Cellular: +33 (0) 6 83 70 89 79

E-mail: nicolas.tanala@v-stars3d.com, website: www.nti-measure.com

__________________________________________________________________________________

INCA3, V-STARS, Picture Perfect Measurements are trademarks or registered trademarks of Geodetic Services, Inc. All other brand and product names are trademarks or registered trademarks of their respective owners.